Channel Glass Specs: Sizes, Tolerances & Selection Guide

2025-09-30

Channel Glass, a versatile architectural solution, is available in widths of 22–50 cm, an approximate depth of 6 cm, and heights up to 7 m. The self-supporting profile carries its own weight without additional horizontal supports and is commonly installed horizontally. The linear channels lend façades a refined corduroy or fine-stripe appearance. Unlike conventional float glass, Channel Glass forms an internal cavity within the façade, creating an ideal zone for thermal insulation materials.

Channel Glass Specifications

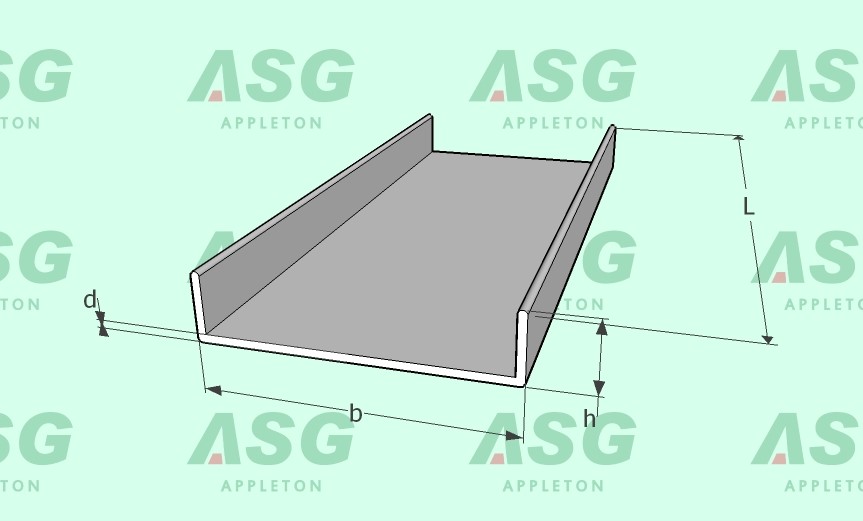

The specification of Channel Glass is defined by its width, flange (wing) height, glass thickness, and the design length required.

1. Channel Glass Width

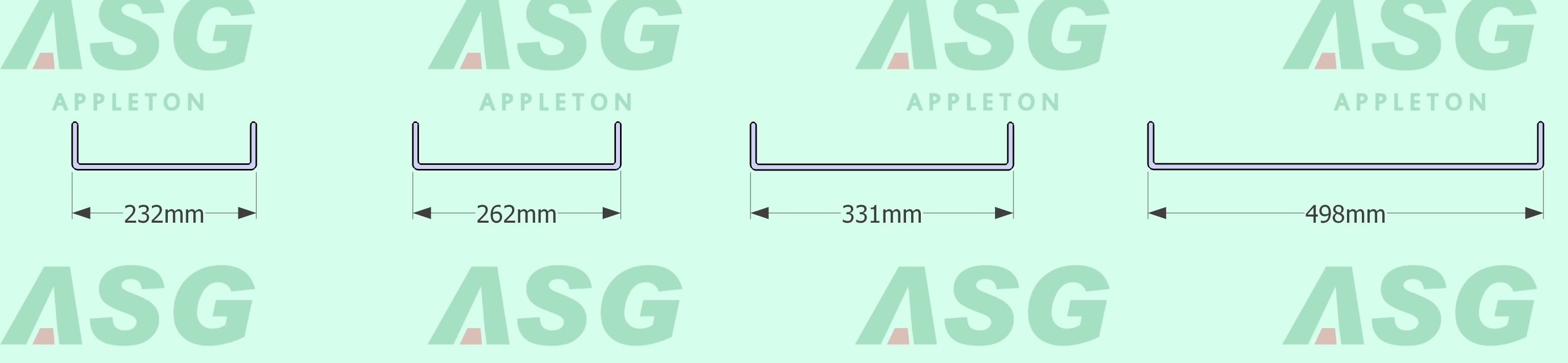

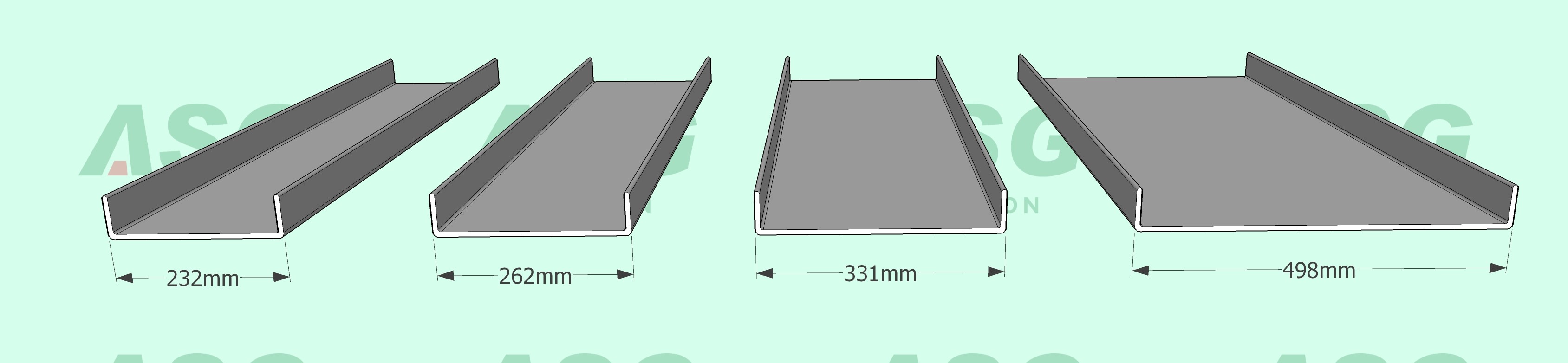

Common standard widths are 232 mm, 262 mm, 331 mm, and 498 mm. Figure 1 shows cross-sections of the four standard widths; Figure 2 presents a three-dimensional view.

Image 1: Cross-sectional diagram of standard-width Channel Glass

Image 2: 3D view of standard-width Channel Glass

2. Channel Glass Flange Height and Glass Thickness

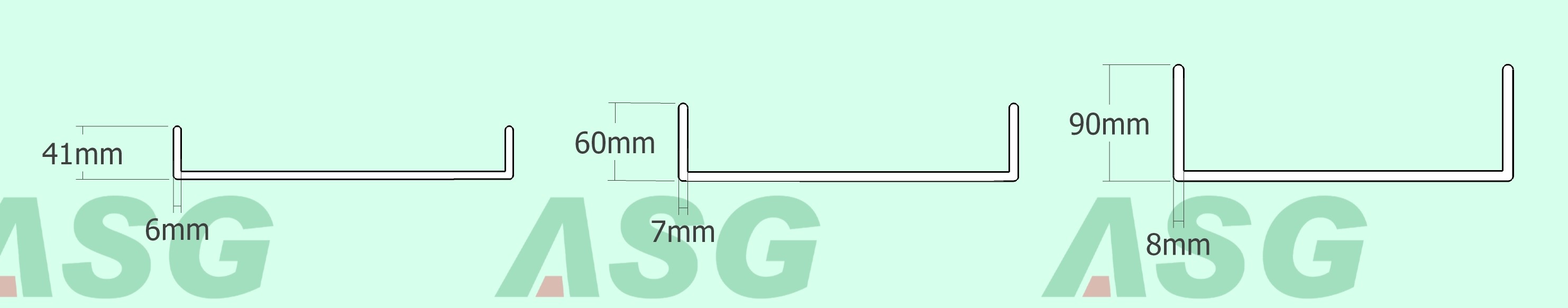

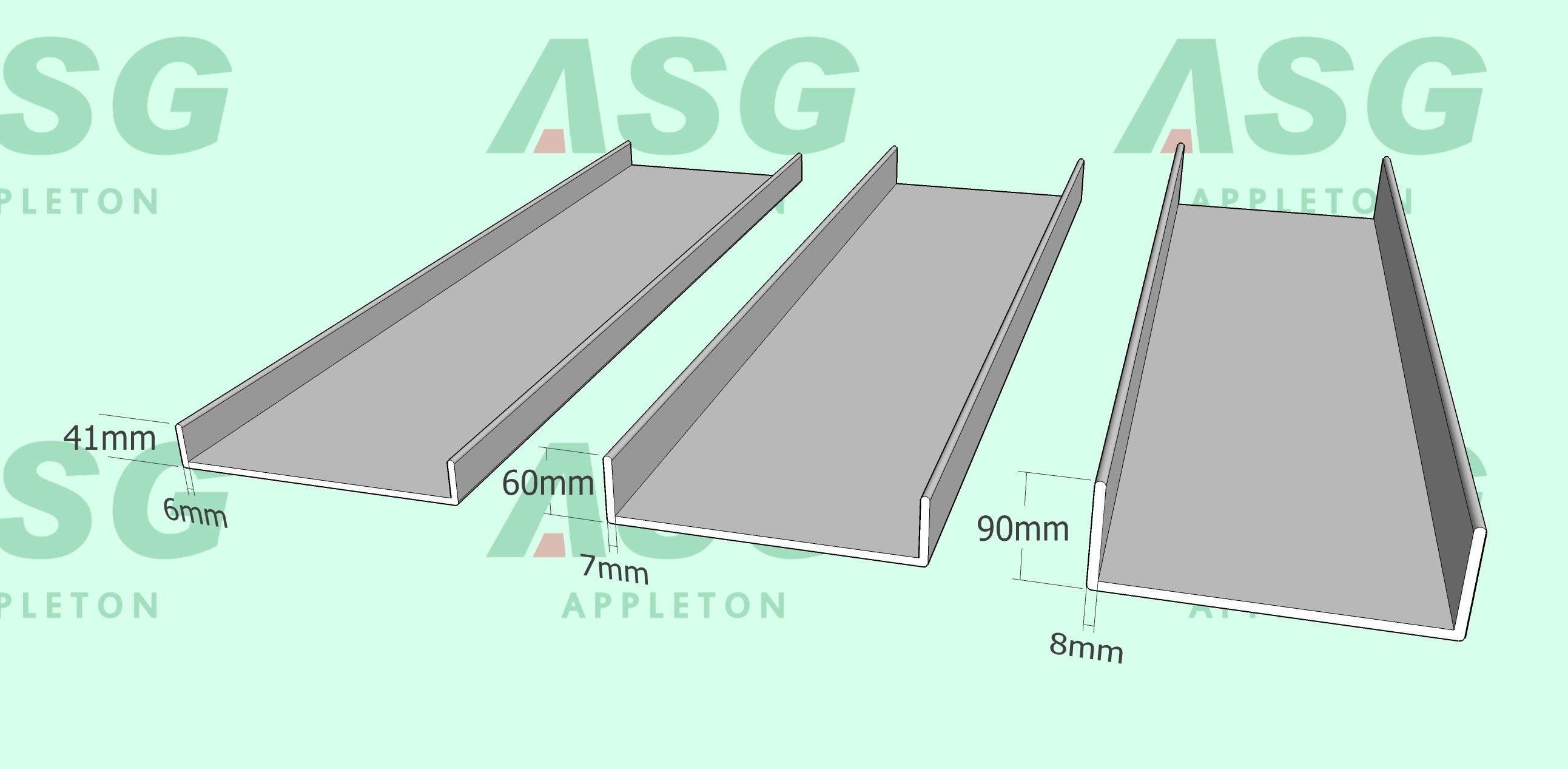

Three standard flange-height/thickness combinations are available: 41 mm with 6 mm thickness (41×6), 60 mm with 7 mm thickness (60×7), and 90 mm with 8 mm thickness (90×8), as shown in Figure 3. A higher flange and thicker glass increase the section modulus, thereby improving wind-load resistance. In general, 41×6 is suited to interior partitions, 60×7 to exterior applications and curtain walls, and 90×8 to locations with high wind-pressure requirements.

Image 3: Cross-section showing flange height and glass thickness

Image 4: 3D view showing flange height and glass thickness

3. Channel Glass Length

Maximum producible length varies with width and thickness; see Table 1 and Figure 5.

For projects with special design requirements, Appleton can supply custom sizes. Our 35-meter continuous tempering furnace (non-reciprocating) can mass-produce K25/90/8 (262×90×8 mm) Channel Glass up to 11 meters in length. Final use must account for wind load and other engineering constraints.

Table 1: Maximum standard production lengths for Channel Glass

Image 5: Graphic of maximum standard production lengths

4. Channel Glass Naming Convention

Channel Glass is designated by width, flange height, and glass thickness. For example, a 262 mm-wide profile is referred to as K25. If its flange height is 60 mm and thickness 7 mm, it is K25/60/7. If the flange height is 41 mm and thickness 6 mm, it is simply K25. See Table 2 for details.

Table 2: Channel Glass naming conventions

In practice, naming may also reflect properties and processing—such as tempering, low-iron, and sandblasting. For instance, “K25/60/7 tempered low-iron Channel Glass” denotes a low-iron, tempered profile measuring 262 mm in width with a 60 mm flange and 7 mm thickness.

5. Dimension Tolerance

Dimensional tolerances directly affect curtain-wall sealing, appearance, installation efficiency, cost, thermal performance, and maintenance. Appleton manufactures in strict accordance with EN 572-7, with tolerances as follows:

• Glass width (b): ±2.0 mm

• Glass thickness (d): ±0.2 mm

• Flange height (h): ±1.0 mm

• Length cutting tolerance (L): ±3.0 mm

Table 3: Comparison of EU and domestic industry standards for Channel Glass

Image 6: Schematic of Channel Glass dimensions

6. How to Choose Channel Glass Size and Specification

a) Prefer standard sizes: Standard profiles offer better cost-effectiveness, multiple sourcing options, shorter lead times, convenient replacement, and mature compatible aluminum framing systems.

b) Consider wind load: Project wind-load parameters typically determine feasible width, thickness, and maximum length.

c) Consider design intent: Different dimensions produce different façade rhythms and visual effects; align the selection with the architectural expression.