Kao-Ho Hospital Wins 2024 iF Design Award

2024-11-19

Kao-Ho Hospital has been awarded the prestigious 2024 iF Design Award, a globally recognized accolade that highlights innovation, functionality, and aesthetic excellence in design. The award acknowledges the hospital's exceptional architectural concept, which merges structural integrity with a serene and health-focused environment. Designed by the German architecture firm Schneider + Schumacher, Kao-Ho Hospital stood out for its unique blend of sustainability, structural performance, and artistic expression.

The 2024 iF Design Award is one of the highest honors in the design industry, and it is a testament to Kao-Ho Hospital's innovative use of materials and modern techniques. Schneider + Schumacher, in partnership with Tan Lai & Associates Architects in Taipei, have skillfully created a building that meets the practical needs of a hospital while offering an inspiring architectural form that integrates seamlessly with the surrounding cityscape.

Architectural Design of Kao-Ho Hospital

From an architectural perspective, Kao-Ho Hospital embodies a modern and sleek design that balances functionality with aesthetics. The building, located in Kaohsiung, Taiwan's second-largest city, features a seismic-resistant structure supported by Grade 8 steel frames, ensuring safety even during strong earthquakes.

The hospital comprises eight floors above ground and two basement levels, designed to accommodate clinical spaces, offices, and a biotech research center. Central to the design is an atrium that stretches across eight stories, allowing natural light to fill the building while providing a peaceful green garden in the center.

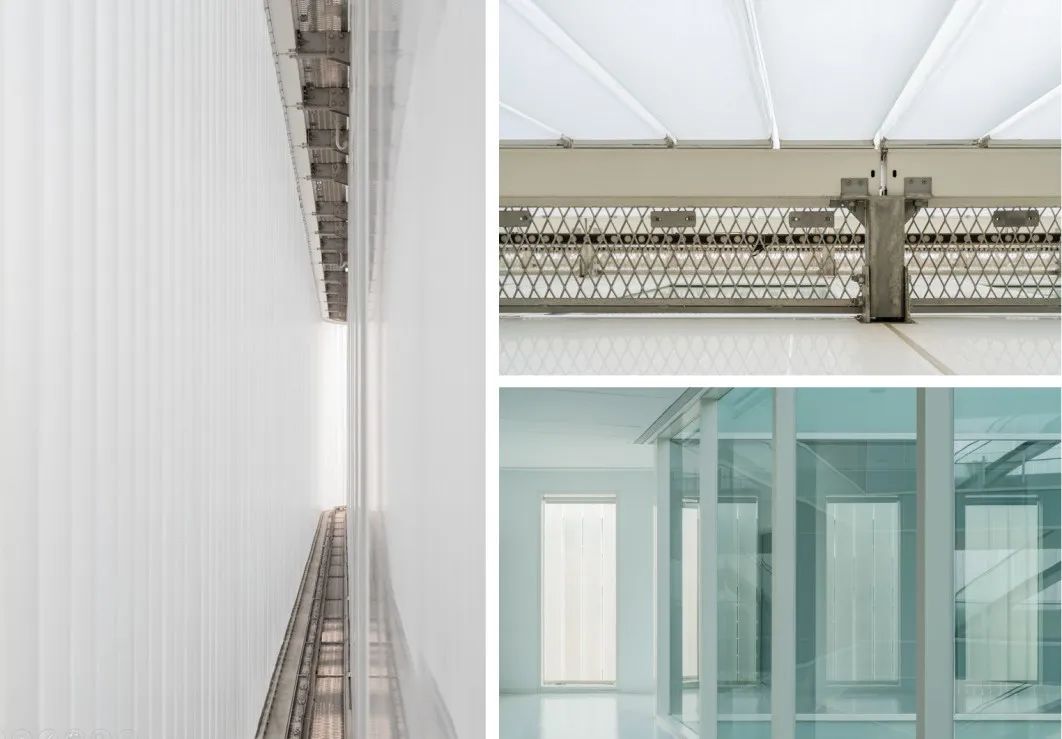

The building's double-skin façade helps reduce dust and noise pollution, enhancing the overall patient experience. The innovative use of channel glass windows enables soft sunlight to illuminate every room while maintaining privacy and a tranquil atmosphere, further contributing to the hospital's healing environment.

Innovative Channel Glass Façade

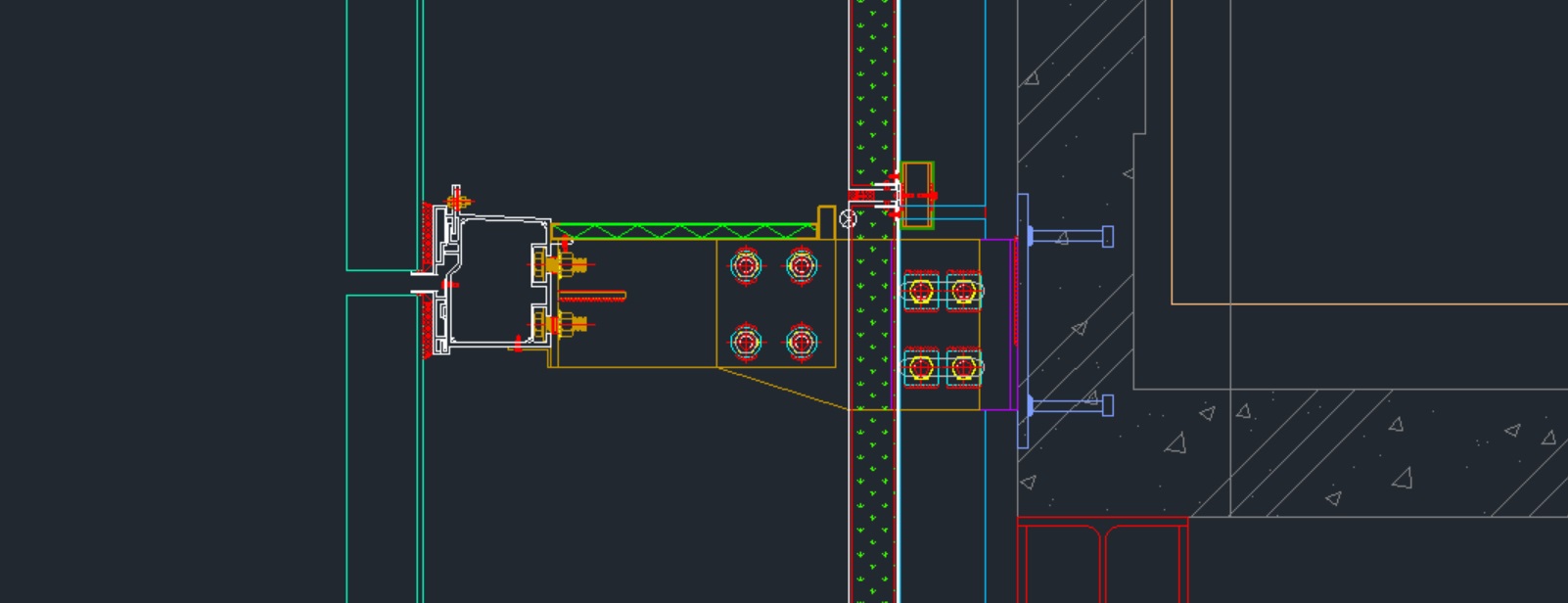

A performance mock-up test verified that the 8mm-thick tempered monolithic channel glass could withstand a wind load of -5.250 kPa, which is 150% of the design wind load. The system passed stringent ASTM E330 and AAMA 501.1 standards, accommodating up to 31.5mm of horizontal and 5mm of vertical movement. These specifications were crucial for ensuring the building's resilience in Taiwan's earthquake-prone region.

The exterior façade of Kao-Ho Hospital is one of its most striking features. The design incorporates an unconventional approach to channel glass installation. Traditionally, channel glass is either vertically or horizontally captured, but in this project, the flanges face outward, and the glass is structurally sealed using silicone, which enhances the visual depth and cleanliness of the exterior. This installation method not only gives the façade a novel appearance but also improves its seismic performance and structural integrity.

The challenges posed by this installation method were substantial. The glass had to meet strict dimensional tolerances to avoid flange deformation or side bends, which could disrupt the clean lines of the multi-layered façade. Additionally, the durability of the fritted surface, which faces outward, was rigorously tested to ensure it could withstand long-term exposure to environmental elements.

Appleton's Contribution to the Project

Appleton played a critical role in the successful completion of the Kao-Ho Hospital project. Starting in 2019, Appleton worked closely with the design and engineering teams for six months to adjust the fritted glass manufacturing process and carry out multiple performance tests. Their expertise ensured the glass met all durability, whiteness, and translucency requirements, balancing both aesthetics and structural integrity.

The company not only adjusted its production methods but also provided crucial data to structural engineers, ensuring the glass would perform under the demanding conditions posed by Taiwan's environmental factors. In early 2020, Appleton began full-scale production of the glass, delivering all 5,091 pieces of ultra-clear, tempered, fritted channel glass that now form the hospital’s elegant, softly illuminated façade.

The successful collaboration between Appleton, the architects, and the engineers resulted in the flawless execution of this landmark project.